The prices for installing a new air conditioner in Malaysia are increasing due rising costs of raw materials, especially copper.

It costs around RM250 to install a new 1HP split unit aircon in Malaysia. This includes mounting the compressor on the outside of your house and the blower inside the room; connecting all the electrical wiring, and connecting pipes for water drainage.

The outdoor compressor and indoor blower also needs to be connected using insulated piping. This piping is usually made of copper. It is used to transport the aircon refrigerant (or aircon gas) from the blower to the compressor and back again. This is what allows it to cool down your room.

The rising cost of copper piping

Copper has been the standard material used in aircon piping for many years. The main reasons why almost all aircon installations use copper piping is because:

- Copper is resistant to corrosion. So, if it is exposed to the sun and rain, it won’t rust

- Copper piping is flexible so it can be bent to fit along your walls

- You can easily join multiple copper pipes together if your aircon unit is far away from your compressor

- Copper can handle the high pressure needed for your aircon gas

But, copper is getting more expensive. As of May 2022, the price of copper had risen by 125% in just 2 years. Today, the cost of insulated copper piping in your aircon installation will cost around RM20 per foot.

If your aircon unit is far away from your compressor, you will need more feet of piping to connect them together. This can increase the aircon installation costs significantly.

“In some houses, you need around 120 feet of piping just to connect one aircon fan unit to the compressor.”

Liew Wan Hoe, Director of TF Greentech

A more affordable solution: Coated aluminium tubing

Instead of using copper piping that is getting more expensive, many households are choosing to use insulated piping made with aluminium instead.

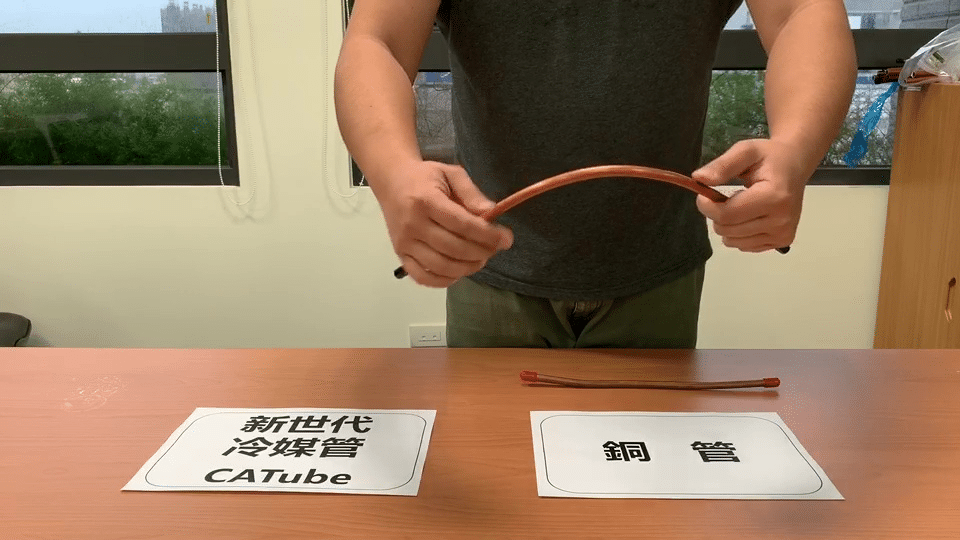

One product that is gaining popularity is Coated Aluminium Tube (or CA Tube), which is lighter, more bendable and flexible, is resistant to corrosion, and just as durable. It works just as well as copper piping, if not better, while (according to TF GreenTech) helping reduce aircon installation costs by as much as 30%. This makes aircon installations cheaper, while lasting just as long.

By switching to CA Tube, property owners can enjoy the following benefits:

1. Reduce aircon installation costs

Aluminium is much more abundant in nature compared to copper, and is also recyclable. This makes it cheaper to manufacture. And when your aircon technician can get their raw materials at lower cost, the savings can be passed on to the consumer.

For larger homes and commercial buildings, the amount of piping needed can go into hundreds of feet. By simply replacing copper piping with CA Tube, you can save enough for an additional aircon unit!

2. Easy and convenient to install

In any aircon installation, the piping needs to be bent to go around walls and beams. CA Tube is more bendable compared to copper piping. That means that your installer spends less time connecting your aircon units to the compressor.

CA Tube is also easy to connect to the inlet and outlet ports of the compressor and blower. The same methods used for copper piping installation can be used for CA Tube. In fact, CA Tube can even be joined to existing copper piping (using a method called brazing) without any leaks.

3. Resistant to leakage and lasts as long as copper piping

For long-lasting installation, the most important things to avoid are freon leaks and corrosion on the inside and outside of the piping.

CA Tube has a high operating pressure, well within the pressures required by the refrigerant gas. It is also highly durable. When it needs to be bent during installation, it will not crack and introduce micro leaks.

And when using your aircon regularly, the nylon coating on the outside of the aluminium resists corrosion due to buildup of water condensation.

4. Made in Korea and SIRIM-certified

CA Tube is made by Hanshin S.Tech, a Korean manufacturer with years of experience. The product itself has been tested and certified to handle high internal pressures, resistant to fatigue and corrosion, and can operate without problems in temperatures of -30 to 120°C.

CA Tube has also been SIRIM-certified to comply with international ASTM B241/B241M standards.

PS: Looking to buy a new aircon unit? We have a lowest price guarantee + extended warranty + installation. Visit Recommend.my Aircon Mart

Do you know any supplier in malaysia